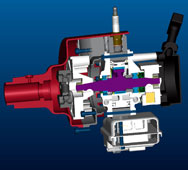

Rotapower® Engine Reliability

Rotapower Reliability WhitepaperHISTORIC RELIABILITY: Freedom Motors has over 40 years of experience testing rotary engines

- OMC rotary engines have accumulated over 4 million working hours

- No OMC engine failures have been experienced due to engine design

- The Rotapower® engine uses bearings with improved life even with double the power

- The Rotapower® engines use improved materials and technology throughout their design

- Pre-production 450cc/530cc and 650cc series models have been tested for over two years without a single design-caused failure

APPLICATION RELIABILITY: The core technology pieces of the Rotapower® have logged thousands of hours in multiple applications

- Neuera flight and nacelle testing

- Skycar flight and nacelle testing

- Marine, ATV and diesel power applications

EXPERIMENTAL RELIABILITY: The dyno testing of the Rotapower® is consistent with lab results from the OMC production dyno data

- OMC found that 2 to 3 mils of wear per 100 hours run time in the lab resulted in > 2000 hours TBO in the field

- Rotapower® seal wear rates are running 0.2-0.3 mils/100 hours experimentally

ANECDOTAL RELIABILITY: Latest generation rotaries are amazingly reliable

- High performance racing teams use dyno tested and sealed rotary engines for multiple seasons without an overhaul.