Rotapower® Engine Performance

Rotapower Performance Comparison WhitepaperHigh Power to Weight Ratio

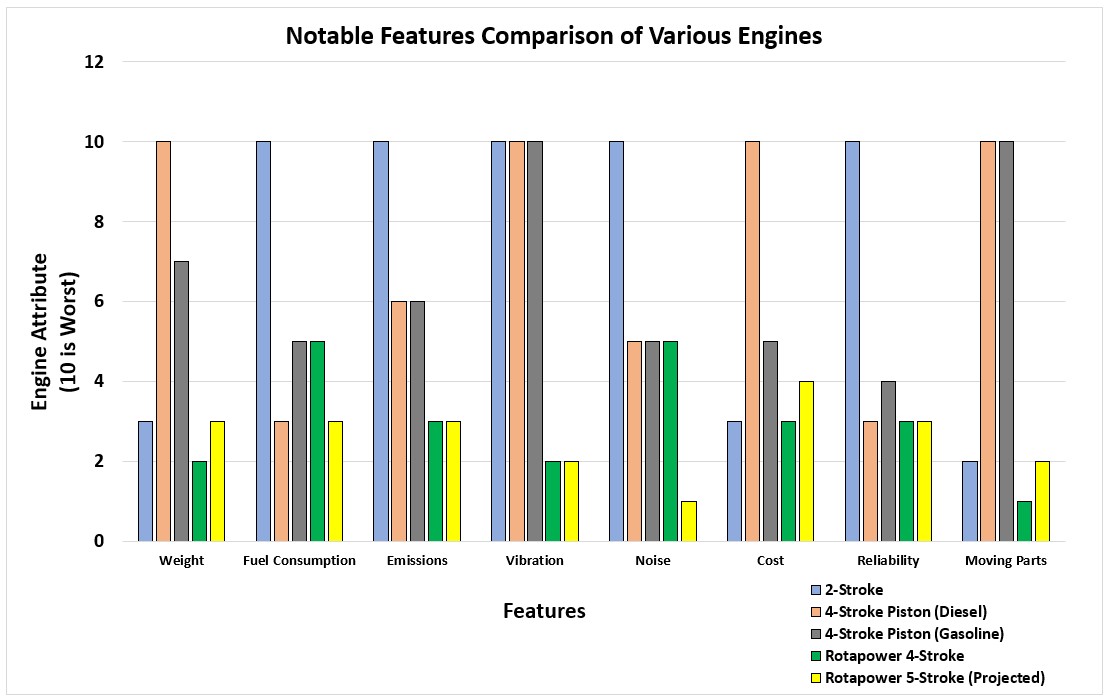

- More than 1.5 HP per pound of installed weight in high-performance versions

- Compares with .6 HP/lb. to 1 HP/lb. for 2-strokes and .3 HP/lb. to .65 HP/lb. for 4-stroke pistons

- Instantaneous torque characteristic identical to 6-cylinder 4-stroke piston (two rotor model)

High Power to Volume Ratio

- (Power Output / Volume) > 100 HP per cubic foot of installed volume

- Compares with 36 HP/ft³ to 50 HP/ft³ for 2-strokes and 10 HP/ft³ to 20 HP/ft³ for 4-stroke piston engines

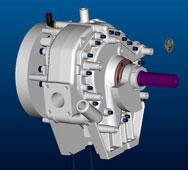

Few Moving Parts

- Only 2 moving parts in a single rotor engine

- Compares to 7 parts for 2-stroke and 24 parts for 4-stroke piston with same instantaneous output torque

- Charge- or air-cooled rotor design eliminates many engine components typical of rotary engines

- Can be overhauled in less than 30 minutes

- Less moving parts means longer life and lower cost

Solid Fuel Economy

- Specific Fuel Consumption < .45 lb./HP-hr ~ (stratified charge). Expect <.4 lb./HP-hr when both stratified charged and direct injected

- Compares to .65 lb./HP-hr for 2-strokes and ~ .4 lb/HP-hr for the best 4-stroke piston

Proven Multi-Fuel Performer

- Demonstrated on gasoline, natural gas, alcohol and propane

- Spark-ignited diesel, kerosene and jet fuel

Very Low Emissions Levels

- See Emissions Performance

- Carbon Monoxide(CO) and unburned hydrocarbon (HC) emissions two orders of magnitude better than 2-stroke, and one order of magnitude better than many industrial or commercial 4-stroke piston engines

- Nitrogen dioxide emissions much lower than 4-stroke piston, comparable to 2-stroke

- Stratified charge together with direct fuel injection reduces fuel consumption and emissions to below 4-stroke piston level

Enhanced Energy at Exhaust

- Acts like a naturally occuring thermal reactor

- Ideal for turbocharge/co-generation applications

- Tolerates high exhaust back pressure for good muffling (like 4-stroke piston)

Low Vibration Levels

- Hard mounted engine can be used as part of the structure

- Perfect radial balance; allows rigid mounting

Modular Design

- Stacking of rotors easily extends range of available power